|

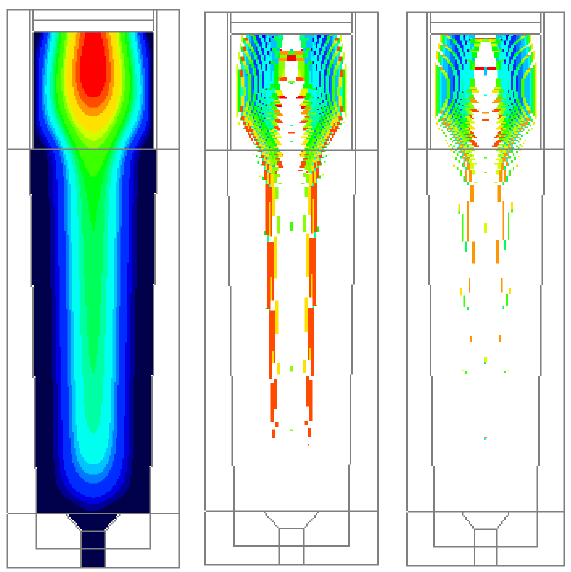

Ingot Solidification Simulation A-Segregation Prediction - service offered by Industrial Soft - |

|

Through A-segregations prediction service you can check if the ingot size, shape and the chemical composition of your steel allows you to have a forging product free of A-segregations and homogeneous mechanical properties. A-segregations prediction module, based on the mechanism proposed by K.Suzuki and T.Miyamoto from Japan Steel Works Ltd. and developed by Industrial Soft is employed with solidification software SimCADE v.2.0 in this numerical analysis. The pdf file report about your ingot will contain: The report of numerical experiments will help you to: The conclusion section comes with practical recomandations that will help you to take better decisions, save time and energy, reduce materials consumption, avoid the A-segregations detected by ultrasonic test and increase homogeneity of mechanical properties. If you are a forging parts buyer and have the manufacturing records of the ingot, this service will give you tools to negociate the price of the part you want to acquire. More, this service will tell you if the semi-manufactured or forging product you want to buy has homogeneous mechanical properties and is free of A-segregations or not. If you need more info about the method we use please check out our video presentations. To request a quote or if you need more information about this service please use the following contact form. |